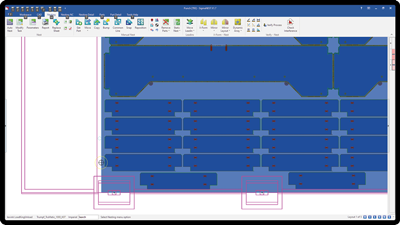

Cutting Machines

Drives Laser, Plasma, Oxyfuel, and Waterjet machines with optimized feed and flow rate for superior part quality and minimum cycle time.

![]()

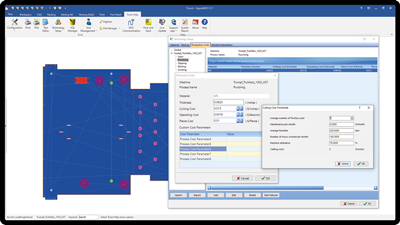

SigmaNEST advanced nesting solution offers a wide range of customizable, modular features to get the most out of your manufacturing operations.

With SigmaNEST, you can:

SigmaNEST drives nearly every type of profile cutting, router, or punch machines to produce premium quality parts using less material and manpower. Our integrated platform uses an easy interface and reduced learning curve so you can choose the machines you like.

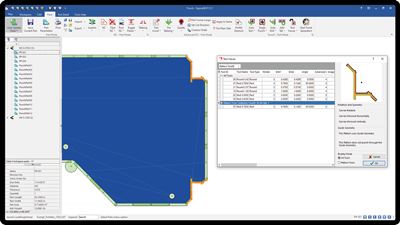

Drives Laser, Plasma, Oxyfuel, and Waterjet machines with optimized feed and flow rate for superior part quality and minimum cycle time.

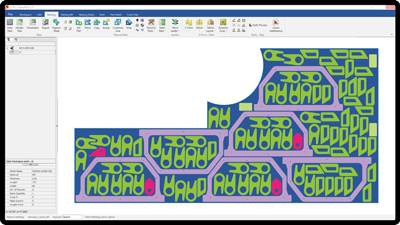

Controls punch or laser/punch combo machines with optimized tool selection, part nesting, and turret management.

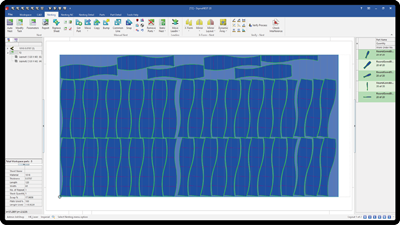

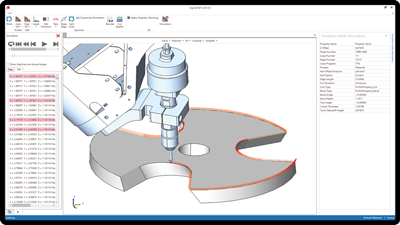

Comprehensive router and drilling solutions with automatic 3D feature recognition. Advanced control for knife and cutting wheel applications.

Advanced programming and simulation for bevel cutting in both 2D and 3D applications of steel plate and tube, wood and composites.

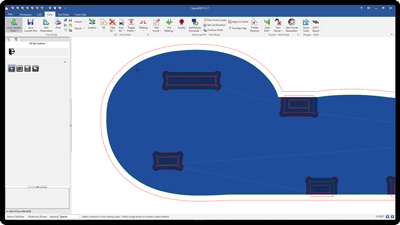

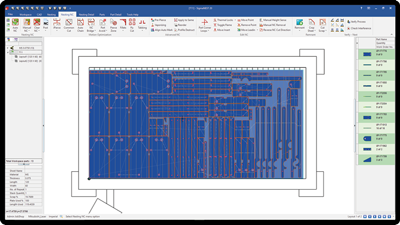

Use less material through higher nest yield–most customers save more than 4% on material when switching to SigmaNEST

Experience a variety of options to reduce pierces, save cutting time, and accurately cut your parts. Consequently, this comprehensive approach results in ROI by optimizing material utilization, machine motion, manpower, and data management.

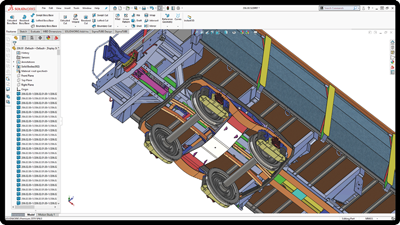

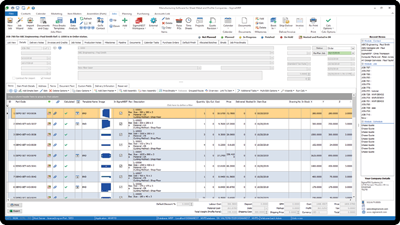

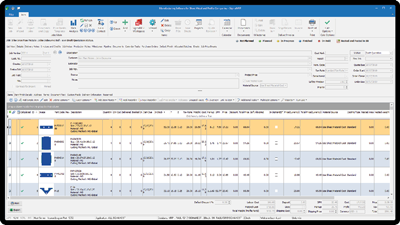

Smart time-saving CAD import recognizes 2D parts or 3D assemblies, and automatically calculates part cost and cutting time

Streamline business with instant quoting, automated work orders and BOMs, job tracking, scheduling and integrated production data

SigmaNEST is one programming software for all simple and complex machines – including punch, profile, and combination

Five package levels with modular features for small job shops to steel service centers to high-volume OEMs.

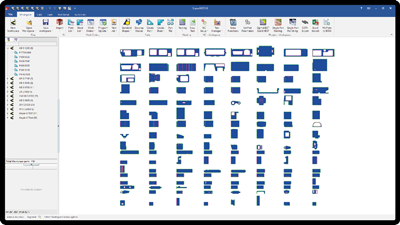

Easy Automatic Nesting

High Efficiency Nesting

Advanced Nesting for Complex Profiling

Advanced Nesting for Higher Volumes

Advanced Nesting for Higher Volumes